Properly Oiled Train Jewel Train jewels must be perfectly clean before any lubrication is applied. It is preferable for lubricants to be applied directly to the oil cup after installing […]

American Watchmakers - Clockmakers Institute

Supporting and Advancing Horology through Education and Cooperation

The American Watchmakers-Clockmakers Institute in conjunction with our industry partners has established a set of minimum standards which all watchmakers should meet. The document, Standards & Practices for Watchmakers, outlines these standards and the details of our certification exam.

A Visual Reference of specific standards is below which can be used by watchmakers, employers, and consumers to judge the quality of workmanship.

Barrel Condition

The barrel complete with mainspring is the power source for the watch, and its condition is very important. The barrel should be completely clean and free of any scratches or […]

Battery Well

When replacing the power cell in an electric watch, it is extremely important to pay attention to the battery well. The battery well often provides direct access to the gear […]

Buckle or Bracelet Clasp

We often focus on the watch movement, but the case and bracelet are just as important. The case and bracelet should always be thoroughly cleaned before returning the watch to […]

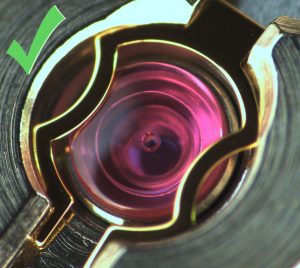

Cap Jewel Preparation

Properly Oiled Cap Jewel The standard for oiling cap jewels includes perfectly clean jewels with oil expanding to fill an area with a diameter equal to between 1/2 and […]

Case Backs

An excellent watchmaker should be able to open and close a watch back without leaving any marks. Very faint scratches may be acceptable in the bottom of a case notch […]

Cleanliness and Condition

All components must be perfectly clean and in good condition. No particles of dust, debris, or lint are acceptable. The parts should be inspected for damage or wear. Some items, […]

Dial & Crystal Cleanliness

The cleanliness and condition of the dial and crystal of the watch are extremely important. These areas are constantly viewed by the owner and are the first and sometimes only […]

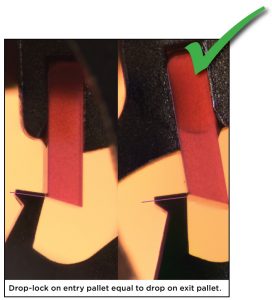

Drop-Lock

Drop-lock occurs at the instant when the drop ends and the escape wheel tooth contacts the pallet stone. It is measured as the distance between the corner of the pallet […]

Escapement

Proper adjustment and handling of the escapement is absolutely critical to the function of the watch. It is quite complicated and many books have been written on the topic. We […]

Guard Pin Shake and Horn Clearance

The guard pin and fork horns are essential components for providing safe action of the escapement when the watch receives a strong shock. The escapement will function normally without them […]

Hairsprings

When adjusting balances with the Etachron regulating system, the hairspring should be centered perfectly between the two regulating pins when the balance is at rest at the dead point. The […]

Hand Alignment and Division

Alignment: The minute hand should point directly at the 12 o’clock (60 minute) marker when the hour hand is perfectly centered on any and every hour marker. This is typically […]

Lubrication

The ideal quantities of lubrication on the escapement vary widely by manufacturer and depend on factors such as size and rate of the escapement, as well as whether or not […]

Minute Counter Jumper Springs

In a chronograph with an instantaneous or semi-instantaneous minute counter, the minute counter wheel is independent of the other gear trains of the watch and only has tension during the […]

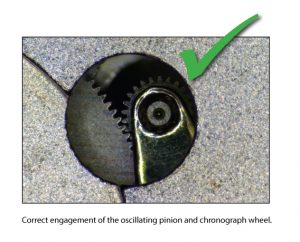

Oscillating Pinion Engagement-ETA 7750 and Similar Watches

The engagement of the oscillating pinion on the ETA 7750 is a topic of its own because it has a clutch mechanism for the chronograph that is not widely used […]

Screw Condition

When watch servicing is complete, the condition of the screws in the watch should be as good as when the watch was received and, ideally, as good as when it […]

Shellac

Proper shellac is essential to maintain the position of the pallet stones in the fork. Poorly applied shellac can interfere with the operation of the pallet fork or fail prematurely.

Standards for the Location and Appearance of Poising Marks on the Modern Balance Wheels

The poising of balance wheels is typically performed at the factory. Re-poising of the balance wheel is often necessary when a balance staff is replaced or there are other changes […]

Stem Cutting

When cutting and preparing a stem to be fit to a crown, the stem must be handled in a way that no damage is done, especially to the threads, hubs, […]

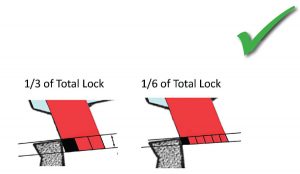

Total Lock/Run To The Banking

Total lock is the sum of drop and run to the banking. It must be equal on the entry stone and exit stone. The deign of the escapement determines how […]